Overhung decoiler

Device for uncoiling metal rolls with a width of up to 600 mm before their subsequent profiling.

The decoiler is equipped with a braking system that prevents the roll from uncoiling by inertia.

Our factory produces a wide range of high-performance roll forming equipment for the production of metal siding and facade panels with different profile geometry.

Prepayment 10%

3-year warranty

Each line is intended for a certain type of product (without readjustment to a different profile).

Readjustment is possible on some equipment models (changing the width of the profile, punching additional holes). However, it does not change the product geometry, only its size.

Device for uncoiling metal rolls with a width of up to 600 mm before their subsequent profiling.

The decoiler is equipped with a braking system that prevents the roll from uncoiling by inertia.

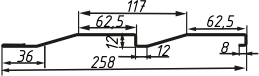

| Installed power, kW | 3,0 |

| Dimensions (L x B x H), mm | 1 640 x 1 420 x 1 500 |

| Load capacity, kg | до 4 000 |

| Roll width, mm | up 500 |

| Internal roll diameter, mm | from 500 до 600 |

| Full diameter, mm | up 1 200 |

| Thickness of rolled metal sheets, mm | 0,4...2,0 |

| Weight, kg | approx. 1 100 |

Narrow decoiler is one of the overhung devices used for the uncoiling of narrow reels. It is used for narrow profiles production lines (siding, light steel thin-walled structure profiles and so on)

A device for fixing a roll of film for the lamination of smooth sheet before profiling.

Laminated siding does not get scratched during transportation and installation; the protective film is removed after the installation so the surface is free of scratches and false images.

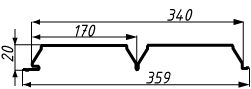

The main unit in the line aimed at profiling the smooth sheet to obtain the desired geometry profile.

Intended for cutting the finished product at the outlet of the rolling mill.

| Sheet thickness, mm | up to 0,6 |

| Cutting cycle, sec | 2 |

| Cutting stroke, mm | 60 |

| Drive | Motor reducer |

Upon cutting the siding, the line automatics position the profile in the cutoff point and command to perform cutting. At that moment the rolling mill is halted.

Intended for the convenience of the finished siding panels acceptance from the shears line.

| Dimensions (L x B x H), mm | from 3,000 x 400 x 1,300 |

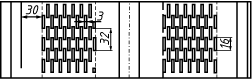

Used in standard line configuration for the profiling of narrow sheets (plasterboard fixing profiles, reinforcing panels, facade panels and so on).

Intended for controlling all the line drives using a thoughtful operator interface.

None of the components are made in China!

Installation of 3D-shears and a bending device for the profile edge flanging and the obtainment of facade cassettes on the collinear panel line is possible.