Overhung decoiler

Device for uncoiling the metal sheets and their further feed into the rolling mill. Equipped with automatic control system.

Roll forming machines allow profiles of specific geometry from a roll of galvanized metal with polymeric coating.

Prepayment 10%

Warranty 3 years

Device for uncoiling the metal sheets and their further feed into the rolling mill. Equipped with automatic control system.

| Installed power, kW | 7,5 (11) |

| Dimensions (L x B x H), mm | 2 480 x 1 730 x 1 830 |

| Load capacity, kg | до 10 000 |

| Roll width, mm | 1 250 |

| Internal roll diameter, mm | от 480 до 620 |

| Full diameter, mm | 1 500 |

| Thickness of rolled metal sheets, mm | 0,3...2,0 |

The decoiler may be equipped with a mobile charging and lifting trolley. The trolley is required for unloading the crane equipment, which is constantly involved in the offloading of profiles and the engaging of new rolls.

The decoiler may be equipped with hydraulic unclamping device (for fast engaging of rolls) Roll decoilers (types and characteristics)

Cuts the last sheet from the mill in order to quickly change the roll to another color.

Before engaging another roll for the next order, it is necessary to wait until the sheet fully rolls out from the mill into the previous order (no waste).

To do this, the line halts the rolling mill in place where the last sheet must be cut. Cutting is carried out with the help of a cutting machine.

The shears can be equipped with a manual or electromechanical drive.

A device for fixing a roll of film for the lamination of smooth sheet before profiling.

Laminated profiles do not get scratched during transportation and installation; the protective film is removed after the installation so the surface is free of scratches and false images.

A profiling rolling mill performs its main function, i.e. it turns a smooth sheet into a corrugated steel sheet.

Rolling mill is a sheet metal processing machine that uses pressure between the rotating rollers to obtain the desired profile. The mill is a set of rolling stands with an electric drive mounted on a frame.

The geometric accuracy, the quality of production and mill service life depend on the tool manufacturing quality, selected rolling scheme, the number of working stands, the design features of the rolling mill, the power, and the drive design.

| Profile type | Number of mill stands | Weight, kg | Dimensions, mm | Power consumption, kW | ||

|---|---|---|---|---|---|---|

| Length | Breadth | Height | ||||

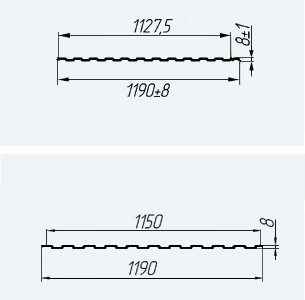

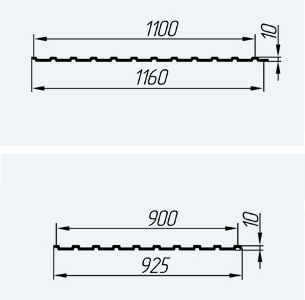

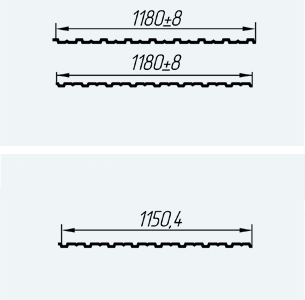

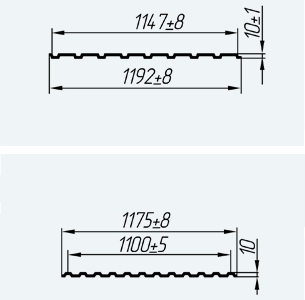

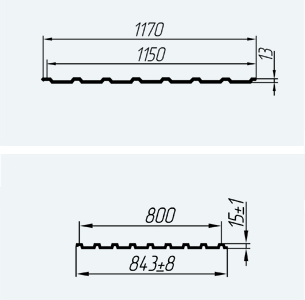

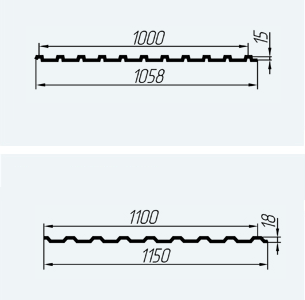

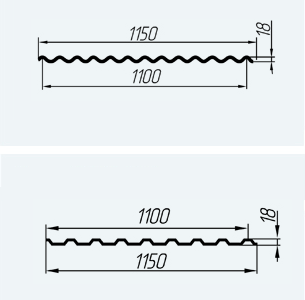

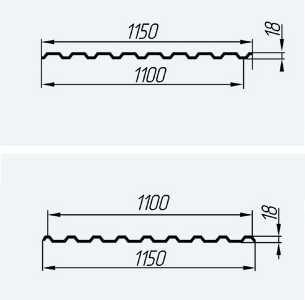

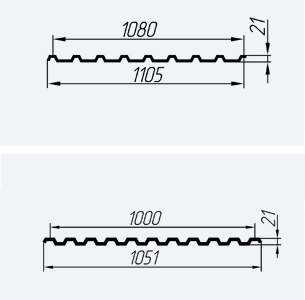

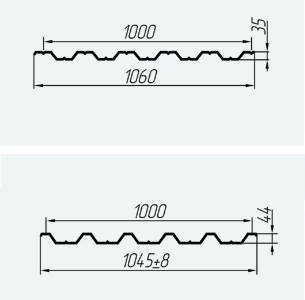

| C-8 | 10 | 5 650 | 7 000 | 1 660 | 1 200 | 7,5 |

| C-10 | 10 | 5 600 | 7 000 | 1 660 | 1 200 | 7,5 |

| C-10 | 13 | 6 800 | 8 600 | 1 660 | 1 290 | 7,5 |

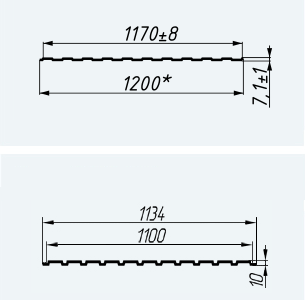

| H-15 | 18 | 9 700 | 9 870 | 1 660 | 1 290 | 2 х 4,0 |

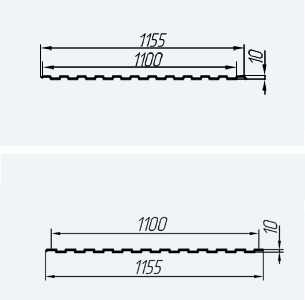

| C-18 | 13 | 6 800 | 8 600 | 1 660 | 1 290 | 7,5 |

| C-18 (wave) | 16 | 9 400 | 9 600 | 1 660 | 1 290 | 2 х 4,0 |

| MP-20 | 13 | 6 800 | 8 600 | 1 660 | 1 290 | 7,5 |

| C-21 | 13 | 6 800 | 8 600 | 1 660 | 1 290 | 7,5 |

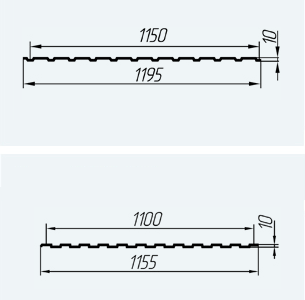

| HC-35 | 16 | 12 500 | 10 500 | 1 660 | 1 290 | 7,5 |

| C-44 | 16 | 12 700 | 10 500 | 1 660 | 1 290 | 7,5 |

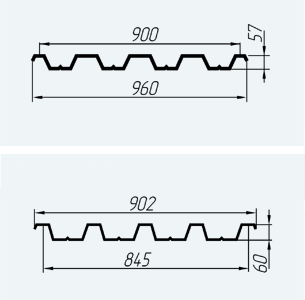

| H-57 | 20 | 16 000 | 15 500 | 1 660 | 2 240 | 2 x 7,5 |

| H-60 | 23 | 17 700 | 16 000 | 1 800 | 2 240 | 2 x 7,5 |

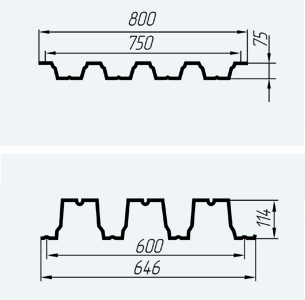

| H-75 | 27 | 20 500 | 17 820 | 1 800 | 2 240 | 2 x 7,5 |

| H-114 | 36 | 60 000 | 35 000 | 1 660 | 2 500 | 4 x 7,5 |

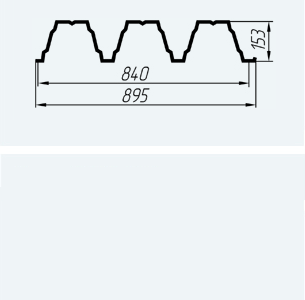

| H-153 | 44 | 80 000 | 46 000 | 1 660 | 2 500 | 8 x 7,5 |

Designed for cutting of the finished product at the outlet of the rolling mill.

| Installed power, kW | from 3,0 |

| Length of products being cut, mm | According to the customer’s requirements |

| Dimensions (L x B x H), mm | from 440 x 1 550 x 1 150 |

| Weight, kg | from 750 |

For corrugated sheets with a corrugation height below 44 mm, guilliotine shears are used. We install grooved shears for cutting profiled sheet H57.

Serves as storage of finished sheets for their subsequent packaging and shipment to the warehouse.

It is possible to install an automatic stacker with ejector and forward and sideways unloading of packs.

Links all units into a line and synchronizes their control.

None of the components are made in China!

In order to form “Dome-type” shaped contours, there is a machine with manual feeding of the profiled sheet. The metal sheets rolled and decorated with the help of our machine are widely used in the construction of corrugated board fences with shaped contours. Custom contour shape (depends on the corrugated board geometry).

The equipment consists of a feeding table and electromechanical 3D-shears. Contour cutting is produced in a single pass.

The machine is supplied on the customer’s request in addition to the profiling line. Cost — 9573 EUR.